The Truth About Flat-Back Elbows

Have questions about flat-back or wear-back elbows? We’ve got answers. Here’s what you need to know.

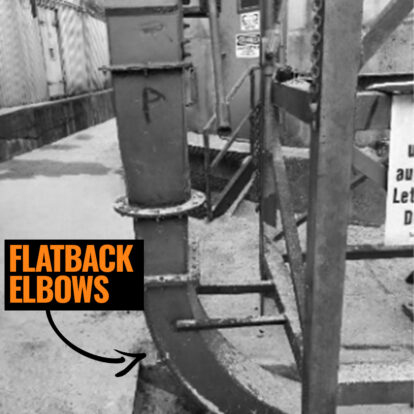

What is a flat-back elbow?

A flat back elbow is a type of pneumatic piping elbow used to connect pipes at an angle. In a pneumatic conveying system, bends and elbows are subject to high levels of abrasion because of the force with which material hits the back of the elbow when making the turn. Flat-back elbows, also known as wear-back elbows, were created to allow replacement of the elbow heel—the section of the elbow that sees the greatest wear. They were created to solve the problem of elbows in pneumatic conveying wearing out before the rest of the piping. They are typically made of AR 235 or AR 400 steel for higher abrasion resistance.

Where are flat-back/wear-back elbows used?

Flat-back elbows (also called wear-back or hard-back) are typically used in piping systems that convey abrasive material, such as high-velocity/low-pressure blowpipe systems for pneumatic conveying of dry materials. They are commonly found in industries such as woodworking, mining and mineral processing. In the lumber, sawmill, and wood processing industries, a flat back or wear-back elbow may be used in conveying systems for green sawdust, wood chips and shavings created by sawing, milling, planing and turning. Abrasion-resistant elbows are needed for fuel delivery systems, which transport sawdust to the kiln area, and for pneumatic transport systems that carry sawdust to bins for waste collection or processing into other products.

How are flat-back elbows attached to the pipe?

Pneumatic transport piping is round, while the cross-section of the flat-back elbow is rectangular, with a removable plate heel. A transition on the inlet is required, to go from round to rectangular. Finally, another transition back to round is required on the outlet to tie back to the pneumatic piping. The transition is typically not AR steel, due to the difficulty of forming. So it becomes one of the first wear

spots on the flat back elbow.

What are the problems with flat-back elbows?

In theory, flat-back elbows work well. But in practice, it is difficult to get a good seal on the replaceable heel, causing leakage and wear. And while the heavy-duty replaceable heel itself may be long wearing, the transitions and remaining body of the flat back elbow are usually plain carbon steel, and they wear through and leak even when the heel doesn’t. In addition, the transitions from round to rectangular and back cause turbulence, acceleration and deceleration of air and material. All of this can lead to increased system back pressure and, eventually, plugging.

There are other problems with flat-backs, too. The typical flat-back elbow is locally made and suffers from the following shortcomings.

- Short Radius: Typically made to fit an existing space, the centerline radius is often down to 3 times the diameter.

- Constricted Cross Section: Made rectangular to accommodate the flat replaceable flat back, these often give up precious square inches of open cross sectional area. This causes increased back pressure and potential plugging.

- Mild Steel Outlet Transitions: Heavy AR plate is almost impossible to form. So even in those cases where a robust flat back heel has been used, the outlet transition wears out quickly. This ruins the whole point of the flat back!

Is there an alternative to the flat-back elbow?

Yes, there is! Induction-hardened steel elbows are an excellent alternative to traditional flat-back or wear-back elbows made of AR steel. Induction-hardened steel elbows offer significant advantages over flat-back/wear back elbows, including:

- Increased service life—up to 4x longer than traditional flat backs.

- Better fit and improved performance, with lower back pressure and fewer leaks.

- Less maintenance time and downtime due to reduced material plugging.

- Significantly lower lifetime costs—as much as 2-3 times lower than flat back elbows. See the cost comparison.

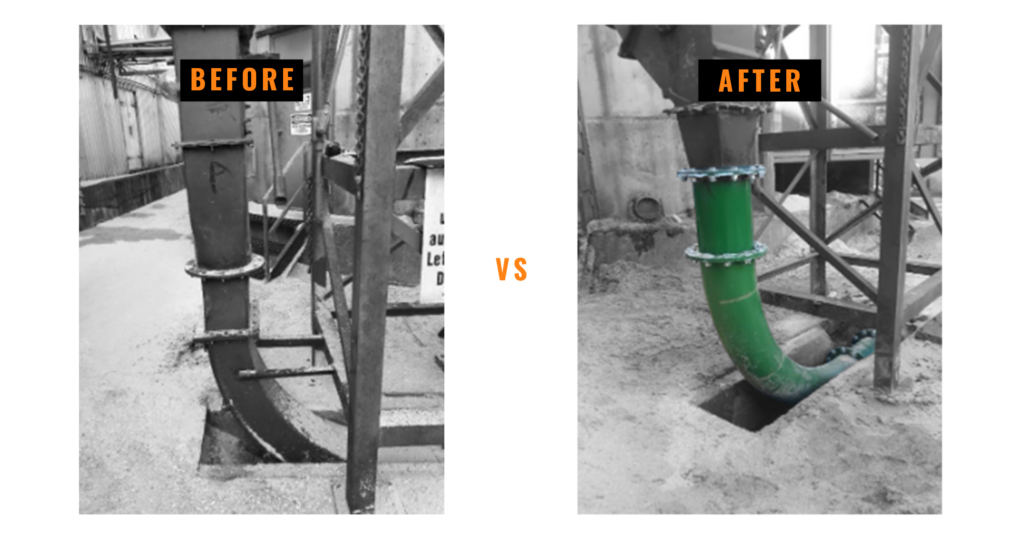

See the Difference!

Traditional Flat Back Elbows Life Expectancy = 6 Months

OUR Elbows Life Expectancy = 2 Year